Discover LASEA’s new platform LS-Plume®, simulation tools for ultrafast laser micromachining

It has been thoroughly demonstrated in the past years that ultrafast lasers are excellent tools for micromachining virtually all types of materials, provided that a good window of processing parameters is chosen so that the resulting thermal effects are negligible.

The ablation topography resulting by irradiation with these lasers typically depend on several factors related both to the laser beam and the material characteristics. As a consequence, the search for the optimal processing parameters that lead to some required ablation dimensions on a given material can be time consuming.

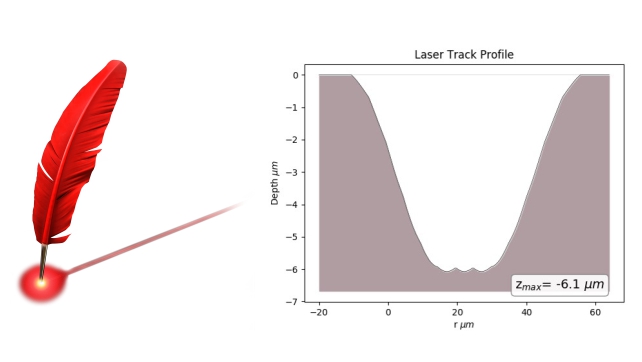

To enhance this parameters search, LASEA developed the application tool LS-Plume®, based on a numerical model that allows estimating the ablation profiles of scanned lines and areas, as well as drilled cavities. The processing parameters required to run the application are the pulse energy, beam waist at the focus, pulse repetition rate, scanning speed and beam tilting angle, whereas the characteristics of the material required are the ablation threshold fluence, the refractive index and the radiation penetration depth.

The results obtained by the application were validated by comparison to the ones obtained experimentally, including for controlled taper drilling, at a wide range of processing parameters. The good results estimated by the application also allow for the optimization of the micromachining process, both energy and time wise.