Extreme precision for critical applications: Laser Micro-Machining of Medical Tubes

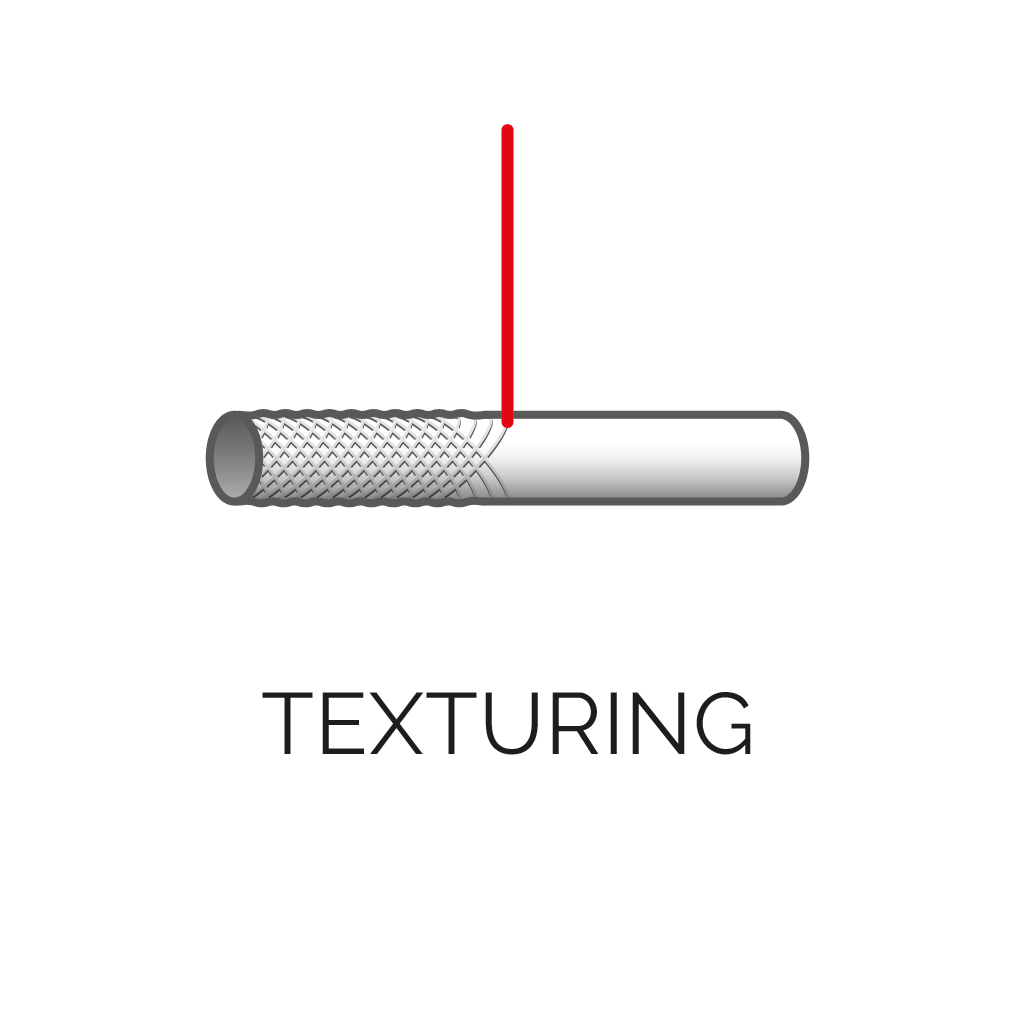

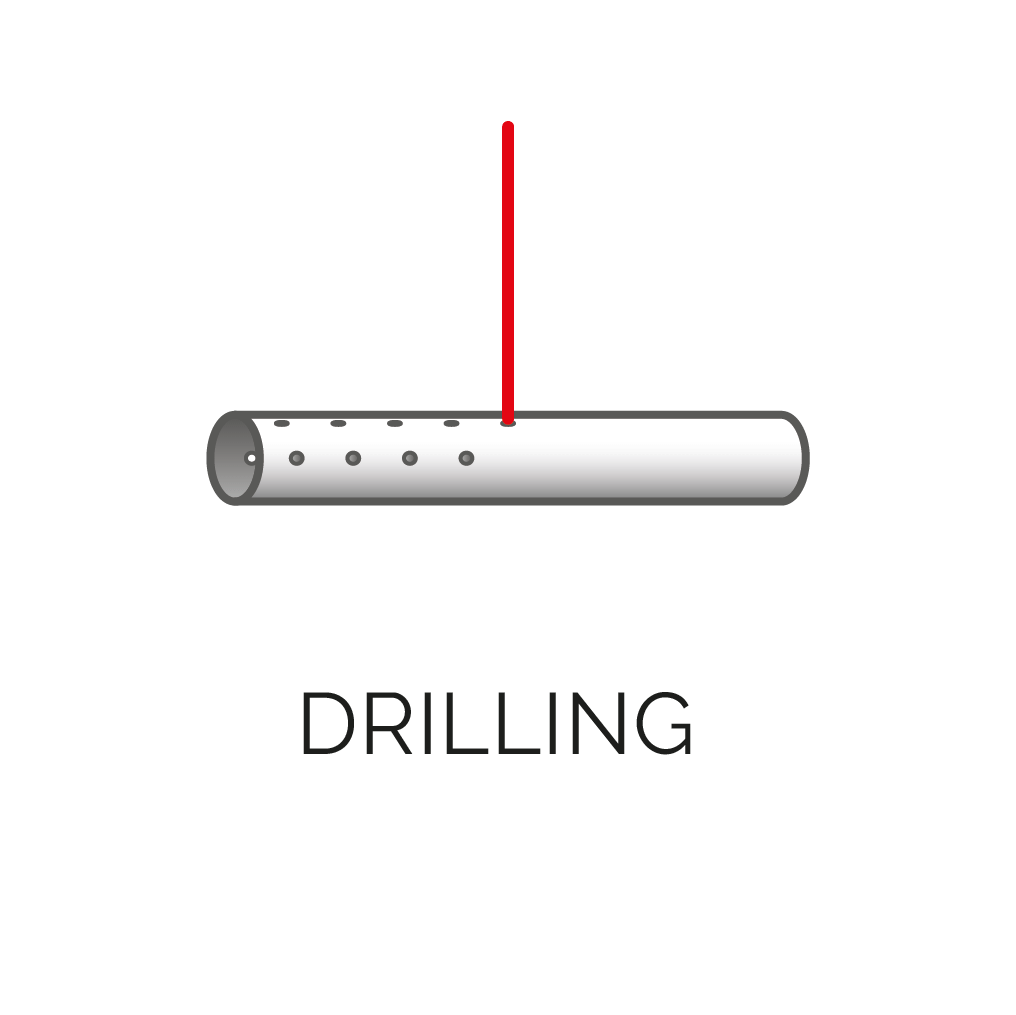

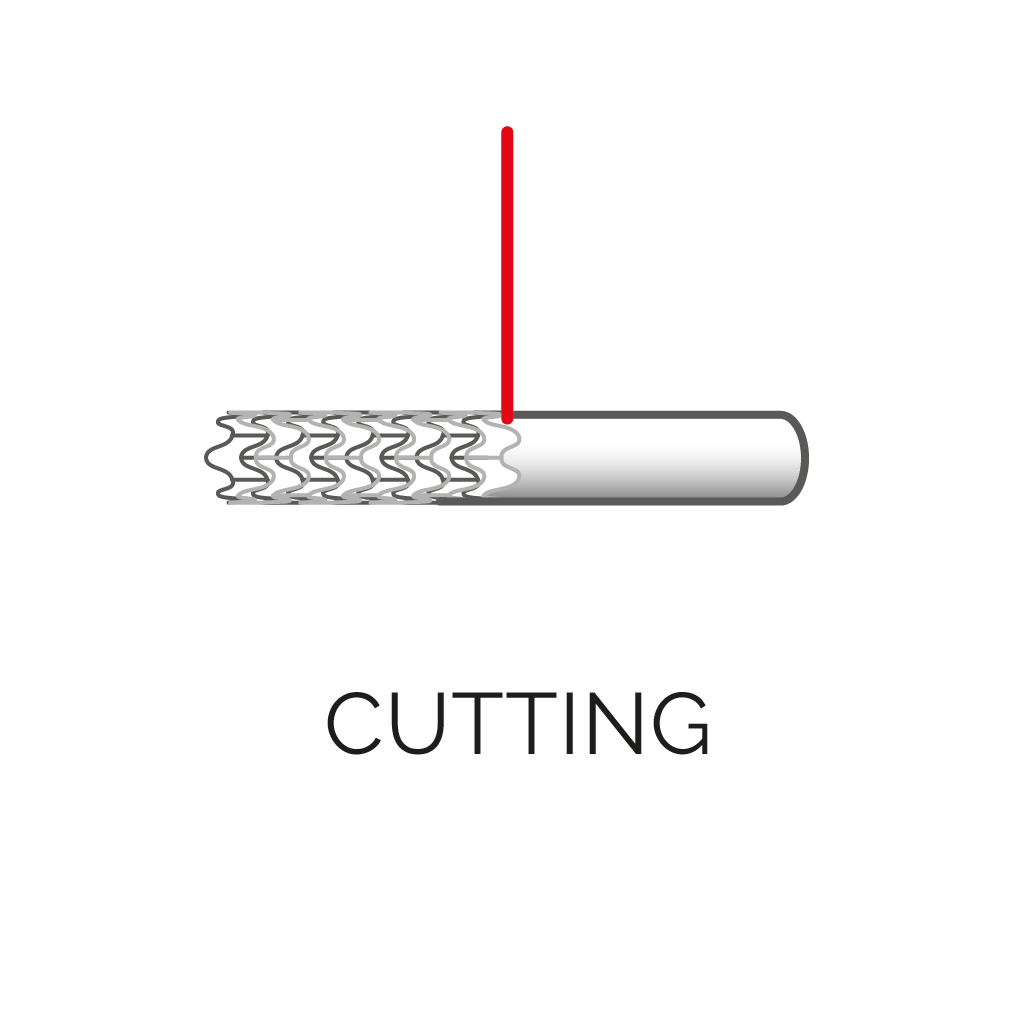

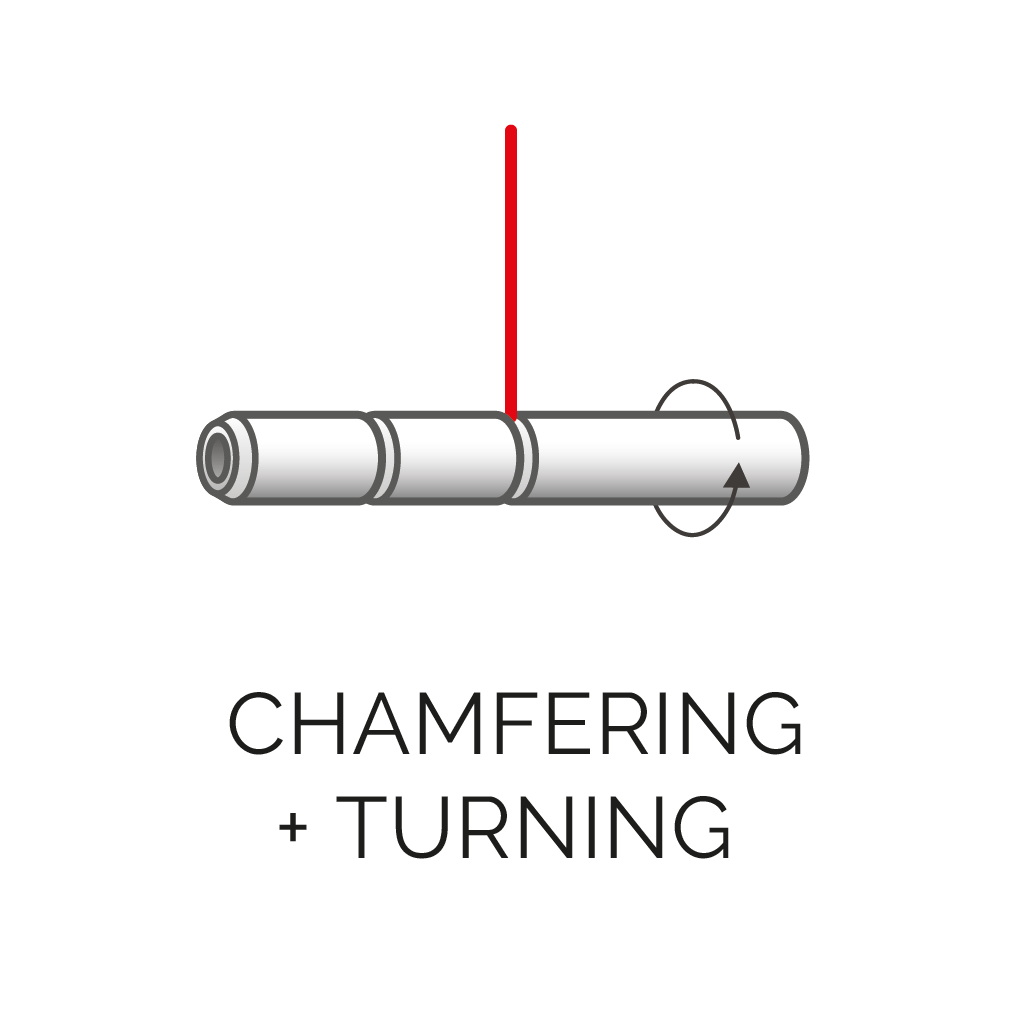

Laser micro-machining of tubes and micro-tubes enables the production of highly precise components essential for advanced medical devices. This non-contact technology allows for ultra-fine cutting, drilling, and surface structuring—even on diameters smaller than one millimeter. Whether for catheters, stents, needles, or miniaturized implants, laser processing delivers unmatched accuracy without thermal distortion or burrs.

Compatible with demanding materials such as stainless steel, nitinol, and biomedical polymers, laser micro-machining meets the stringent requirements of the medical industry. It offers exceptional design flexibility and repeatability while maintaining tight tolerances. This makes it the ideal solution for manufacturing next-generation medical devices that are increasingly compact, efficient, and reliable.

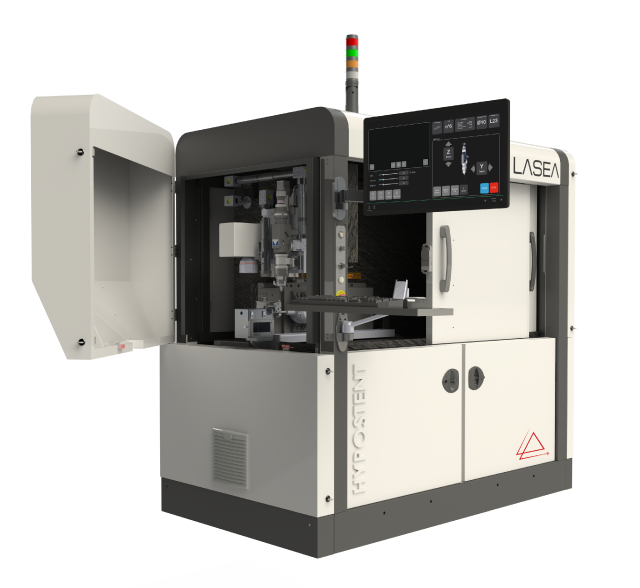

Hypostent laser machine

Our new Hypostent workstation offers the flexibility to create complex designs for diverse medical devices. The addition of an advanced galvo scanner unlocks once-impossible business opportunities!

We support you at every stage of your manufacturing process

The LASEA Group has several test laboratories and a clean room (ISO7 class) where it is possible to test your materials/applications and produce small series runs. Please provide as much information as possible about your project and your contact details. One of our experts will contact you shortly.