This optional module supercharges the way you interact with your laser machine and all the cameras that come with it.

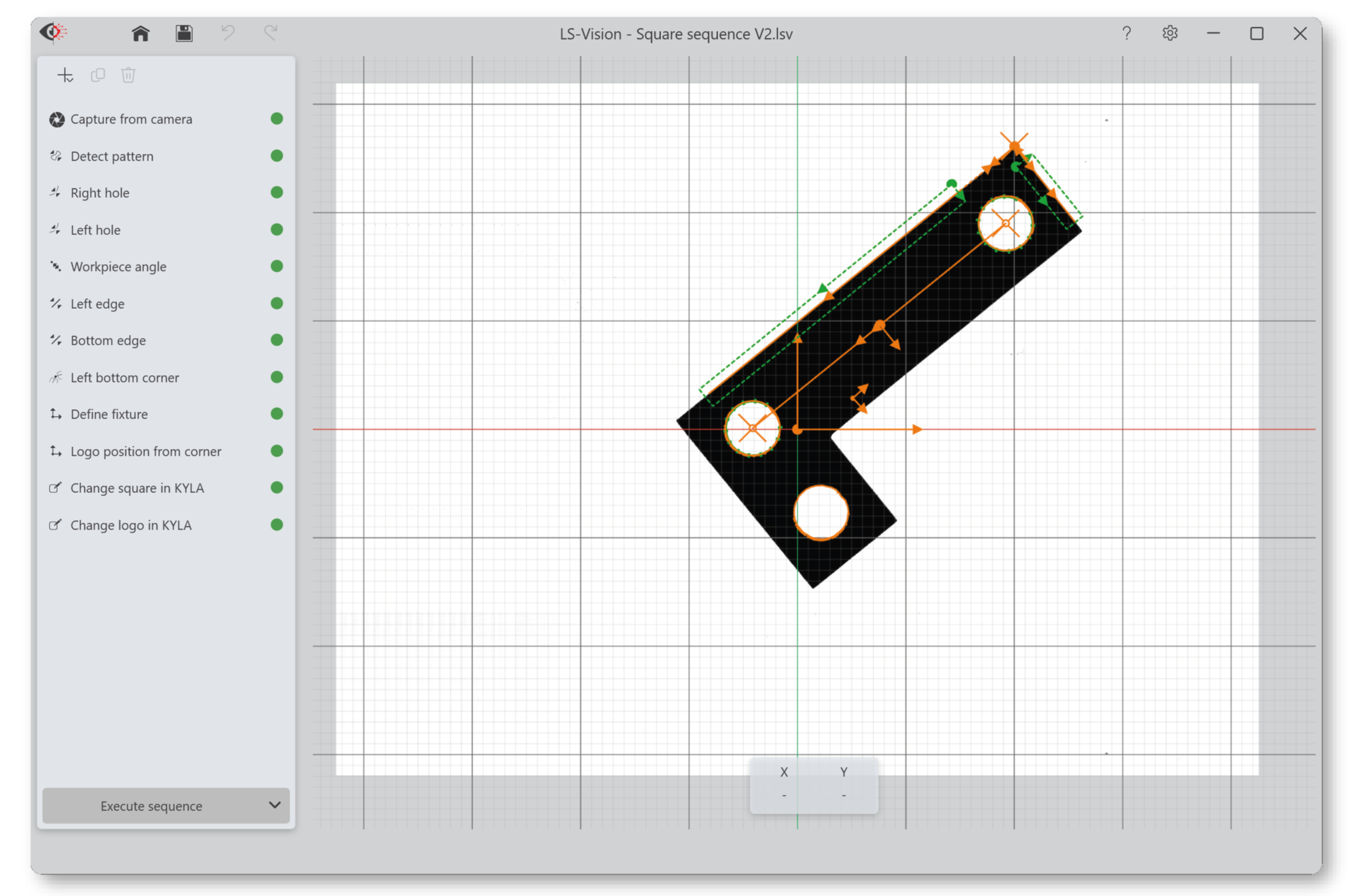

Designed to enhance precision and efficiency, the module automatically captures and analyzes visual data, ensuring flawless execution of your laser process.

Whether it’s for part alignment, quality control or process verification, this tool provides unparalleled accuracy, reducing errors and increasing throughput.

Here are the detailed features of LS-VISION:

Software module integrated in KYLA

- Use it directly from KYLA user interface

Installed with multiple plugins to execute the vision sequence

- 23 plugins already available

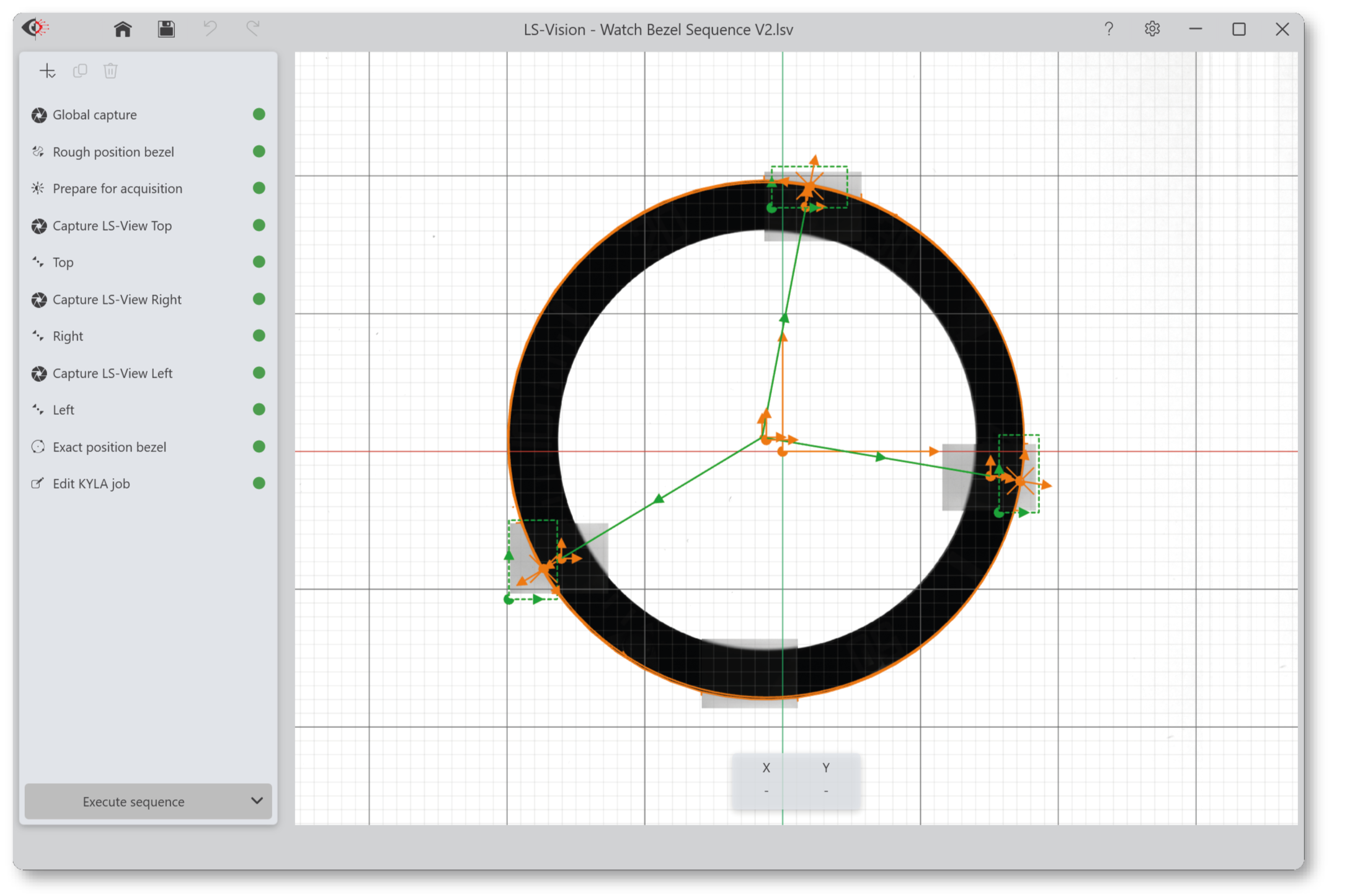

Supports multiples cameras (any camera supported by KYLA can be used)

- Combine large FOV cameras with high precision LS-View camera

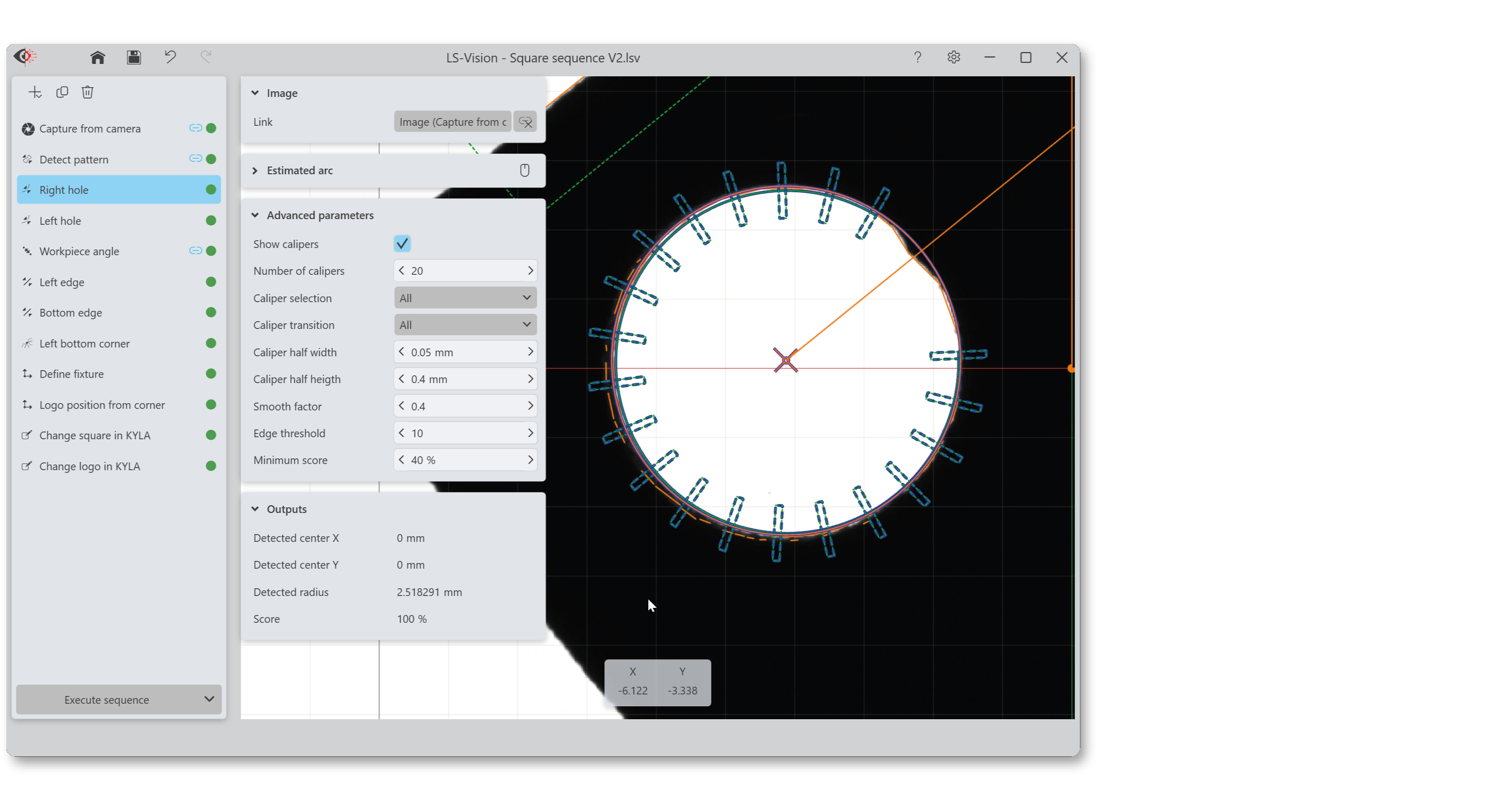

Feature detections

- Detect all sorts of features (edges, angles, holes) automatically using state-of-the-art Halcon algorithms

Automation actions

- LS-Vision can pilot your machine directly

Measurements & calculations

- Elaborate complex Quality Control processes to ensure optimal machining results

Extend and customize the software to your needs

- Use your own Halcon scripts or develop your custom plugins

Offline mode

- Conceive your vision process without using your production machine

Easy to integrate and operate, the LS-Vision Module is the perfect solution for customers

seeking to leverage the power of vision automation to boost productivity and maintain competitive edge.