We functionalise surfaces with nanometric and micrometric textures to meet the extreme requirements of the aerospace & defence industry.

Our engineered textures deliver advanced hydrophobic properties for de-icing and self-cleaning capabilities, while enabling optical enhancements such as anti-reflective surfaces and stealth functionalities.

These treatments also improve thermal management and reduce aerodynamic drag, contributing to enhanced performance and measurable efficiency gains. Additionally our surface texturing can boost adhesion, reduce friction and wear.

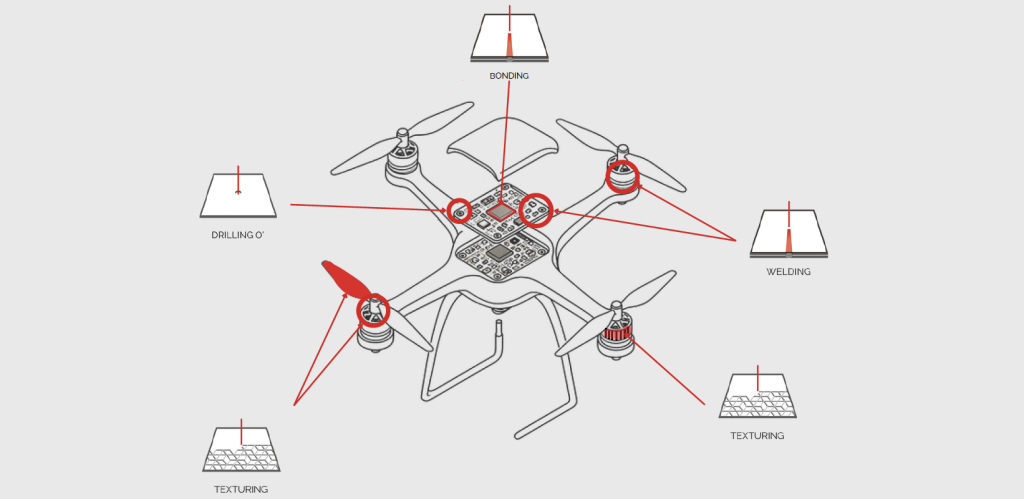

Advanced laser micromachining capabilities

LASEA specialises in ultrafast laser micromachining, utilising femtosecond, picosecond, and nanosecond laser sources. Our systems enable high-precision operations such as cutting, drilling, engraving, thin film removal and surface texturing on a wide range of materials, including metals, polymers, and ceramics. The femtosecond laser technology allows for material processing with minimal thermal impact, ensuring high-quality results without damaging sensitive components.

Micro-welding & micro-bonding of dissimilar materials

Our femtosecond laser systems facilitate micro-welding & micro-bonding of dissimilar materials, such as metals to polymers or transparent substrates to opaque materials, without the need for intermediate layers. This capability is crucial for manufacturing complex defence components where traditional welding methods are inadequate. The ultrafast laser pulses enable localised energy deposition, resulting in strong joints with minimal heat-affected zones.

Surface functionalisation

LASEA’s laser micromachining technology allows for precise surface functionalisation, creating micro- and nano-scale structures that can modify surface properties such as hydrophobicity, friction, wavelength absorption (stealth), heat dissipation, noise reduction and optical characteristics. This is achieved through techniques like laser-induced periodic surface structures (LIPSS) and direct laser interference patterning (DLIP), enabling the development of surfaces with tailored functionalities for defence applications.

OEM laser modules

LASEA designs and manufactures OEM laser modules that can be directly embedded into complex industrial or defence systems. These modules are suited for integration into platforms, targeting systems, striking systems or automated assembly tools used inmunitions or avionics manufacturing. Those OEM laser modules are the result of collaborating with partners on the integration of laser technologies into comprehensive systems, ensuring seamless operation across platforms.

Ceramics

Polymers

Metals

Main Applications

Cutting O°

Drilling 0°

Welding

Texturing

Thin film removal

Contact our Aerospace & Defence specialists

Pascal Durdu – Business Development BeNeLux

+32 (0) 473 55 86 23

pdurdu.ext@lasea.com

Or use the form below: