Laser machines for manufacturing ultra-precise medical devices

To meet the current and future challenges of the medical industry, as it seeks ever-greater precision with optimised cycle times, the LASEA group has designed and developed a range of laser machines and innovative solutions specifically designed in response to the needs of its Medtech customers throughout the world.

The LASEA Group employs over 180 people at 6 sites in Europe and the United States and offers a wide range of equipment at the cutting edge of micro-precision machining technology.

Our team of expert engineers masters both ultra-short pulse focused beam machining (in the femtosecond range) and UV excimer laser photoablation.

This dual expertise means we can cover the majority of industrial production processes specific to the medical sector, for which lasers have become a veritable benchmark tool.

- The LASEA Group has positioned itself as a trusted global partner for players in the medical industry looking for innovative, customised solutions.

Our areas of expertise in the medical sector

Today, the LASEA Group can meet the needs of the following cutting-edge medical technologies:

- Devices for the treatment of cardiovascular and peripheral diseases

- Diabetes treatment

- Neurology

- Ophthalmology

- In-vitro diagnostics

- Micro-prostheses and implants

- Biopsy

- Controlled administration of medicines

In each of these areas, numerous applications have been successfully demonstrated and are now widely implemented in patient treatment.

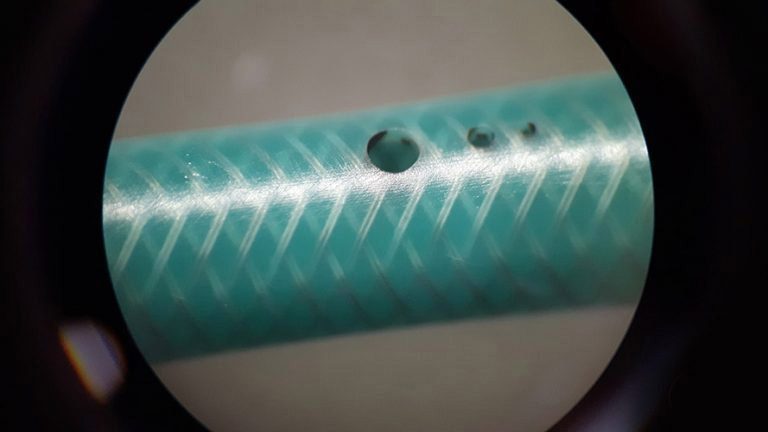

Tube cutting (Stents, Catheters)

Our Lasea laser machines are used to cut, weld, drill, and texture various materials, with the required precision for manufacturing miniaturised medical devices.

- Drilling of calibrated holes in catheters (variable hole shape, size from a few microns to a hundred microns, materials: PEBAX, PU, Silicone, PI, PEEK, etc.)

- Stripping ablation of catheter electrodes after overmoulding operation

- Machining catheter profiles (to facilitate insertion with minimal force or insertion of a ring)

- Perforation of membranes (to control the passage of gas or liquids)

Discover our laser machines dedicated to medical devices

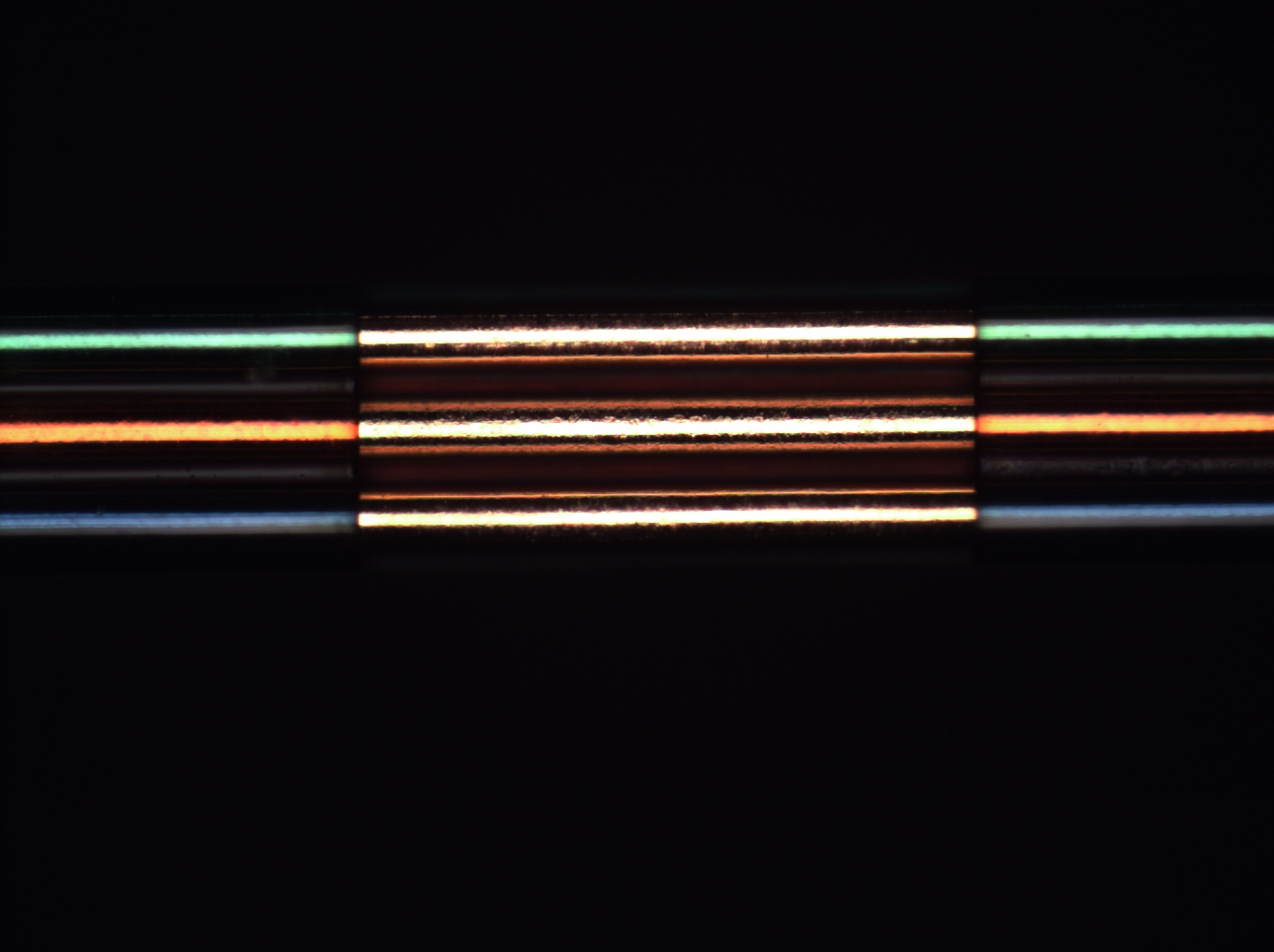

Wires

Our Lasea laser machines are used to cut, weld, drill, and texture various materials, with the required precision for manufacturing miniaturised medical devices.

- Stripping single or multiple wires used in manufacturing diagnostic and ablation catheters

Discover our laser machines dedicated to medical devices

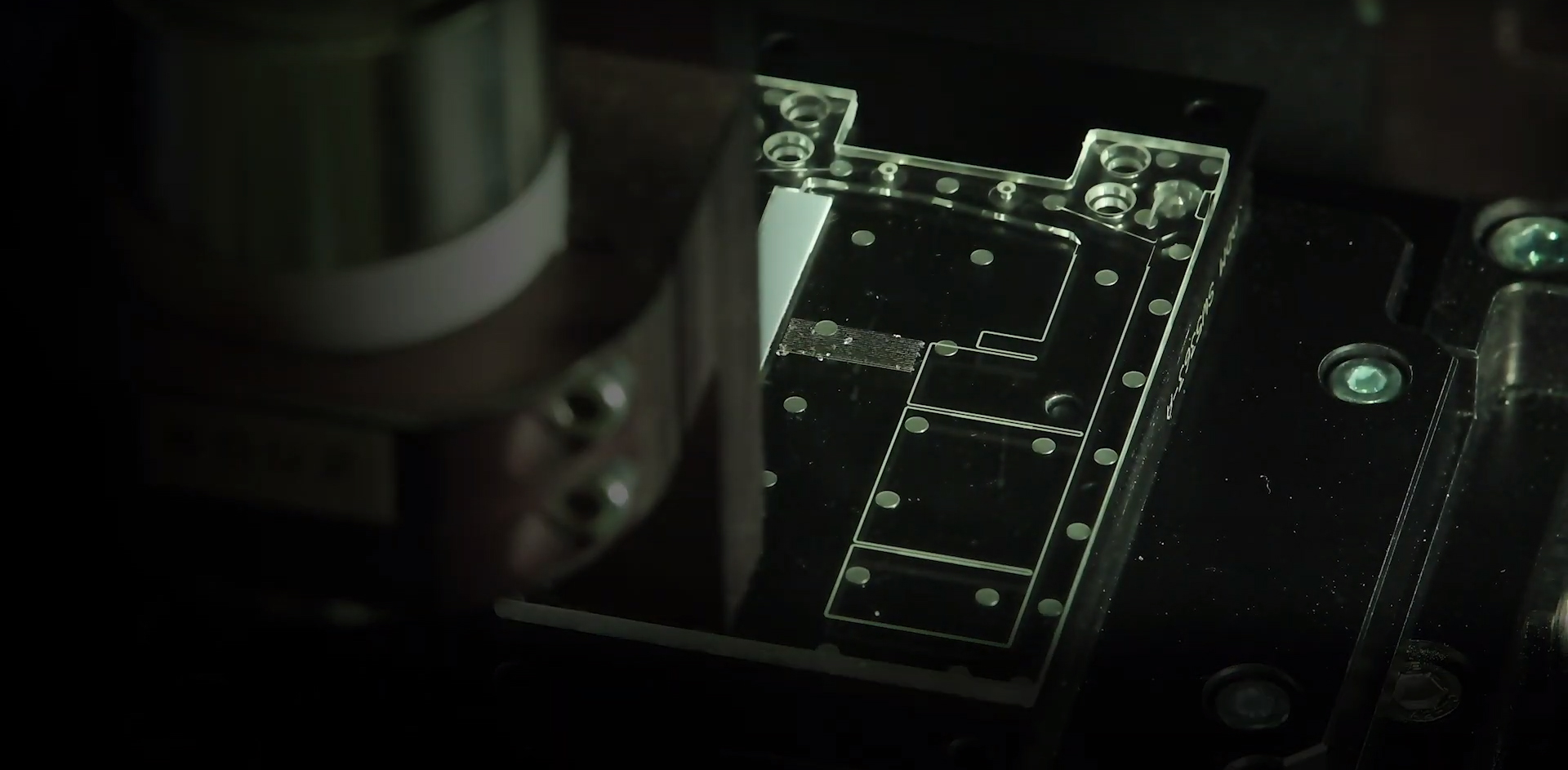

Diagnostics

Our Lasea laser machines are used to cut, weld, drill, and texture various materials, with the required precision for manufacturing miniaturised medical devices.

- Machining of biosensors (to provide precise assay of constants in blood, etc.)

- Micro-machining of glass (e.g. precise grids for cell counting)

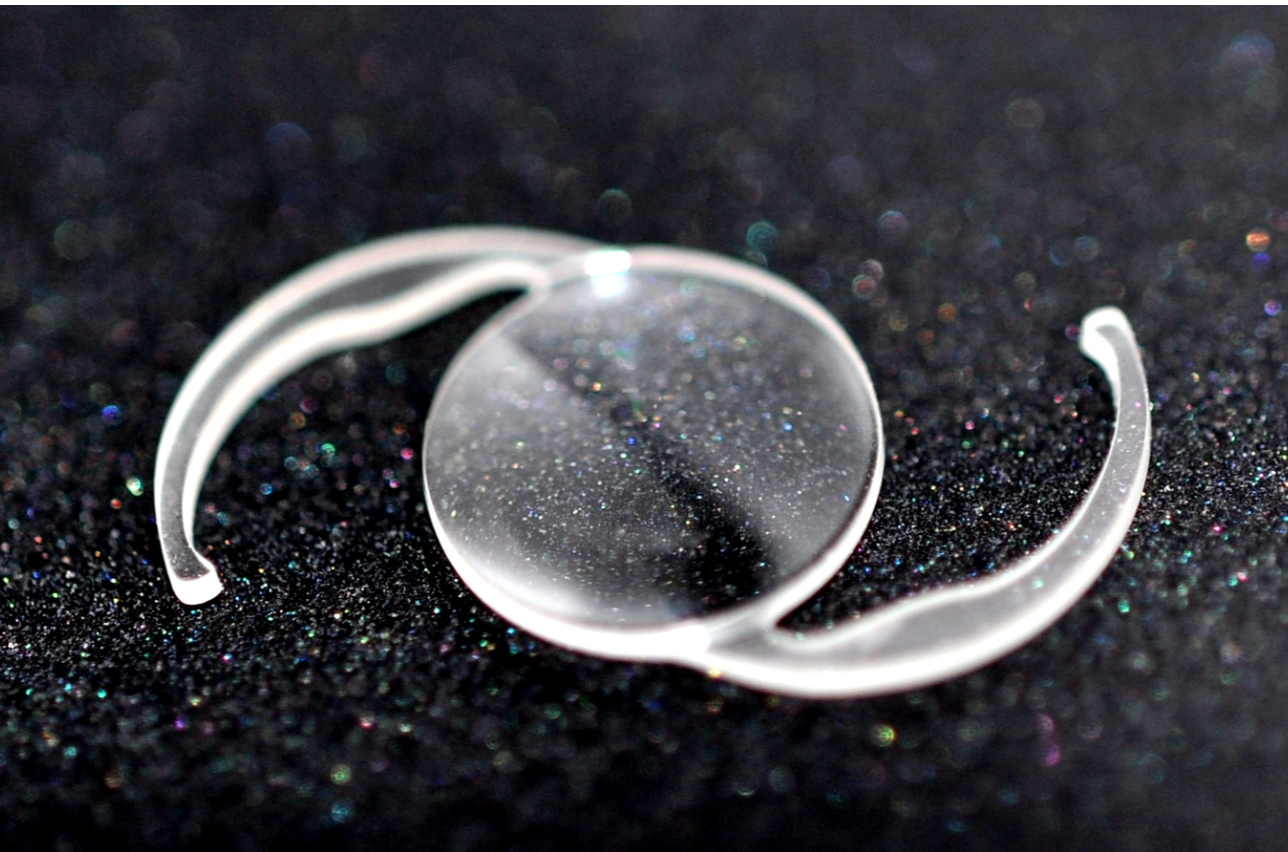

Implants

Our Lasea laser machines are used to cut, weld, drill, and texture various materials, with the required precision for manufacturing miniaturised medical devices.

- Cutting ocular implants (IOL)

- Sterile marking of plastics

- Micro and nano texturing of surfaces to generate anti-bacterial properties in medical devices

- Texturing on dental implants to facilitate osseointegration

Discover our innovative laser solutions for the medical sector

We support you at every stage of your manufacturing process

The LASEA Group has several test laboratories and a clean room (ISO7 class) where it is possible to test your materials/applications and produce small series runs.

Please provide as much information as possible about your project and your contact details. One of our Medtech experts will contact you shortly.